अचूक NTC 5D 9 पॉवर थर्मिस्टर

वैशिष्ट्ये

हे उत्पादन रेडियल लीड राळ कोटिंग प्रकार आहे

लहान आकार, उच्च शक्ती, लाट प्रवाह दाबण्याची मजबूत क्षमता

जलद प्रतिसाद

मोठी सामग्री स्थिरता (बी मूल्य), लहान अवशिष्ट प्रतिरोध

दीर्घ आयुष्य आणि उच्च विश्वसनीयता

पूर्ण उत्पादन वैशिष्ट्ये आणि विस्तृत कार्य श्रेणी

कार्यरत तापमान -55~+200℃

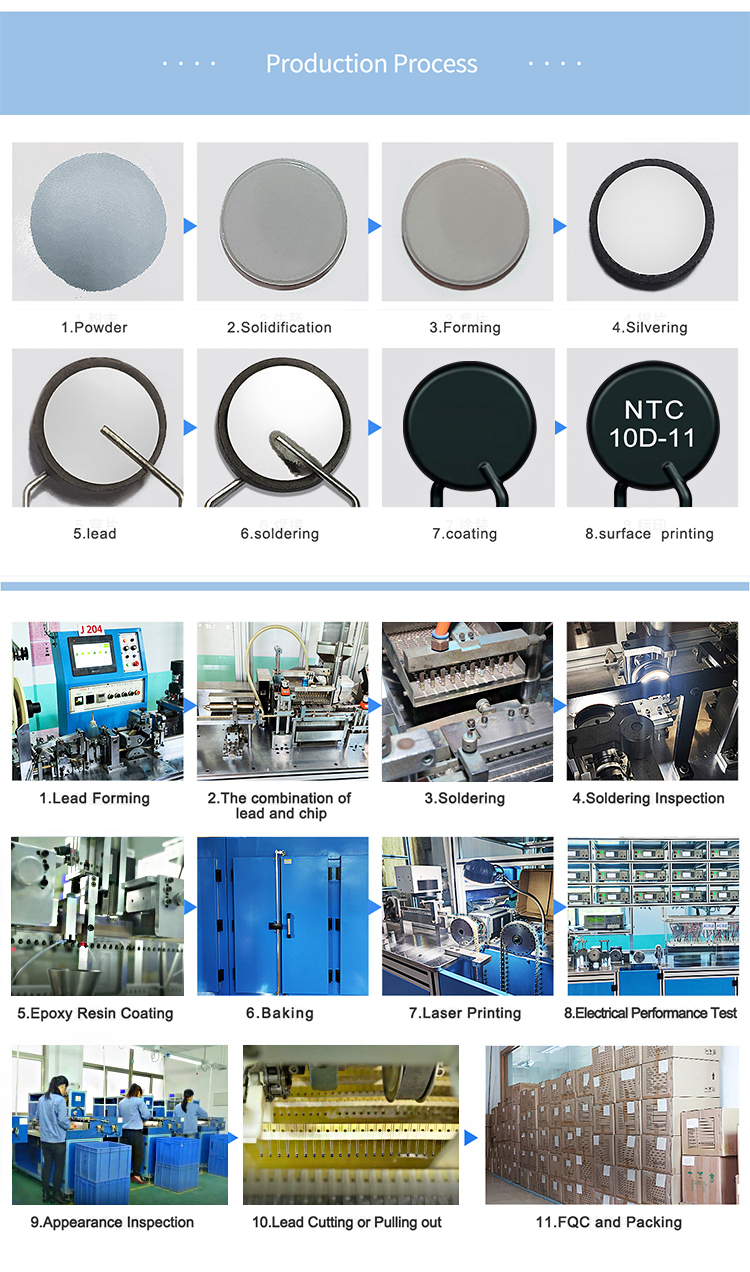

उत्पादन प्रक्रिया

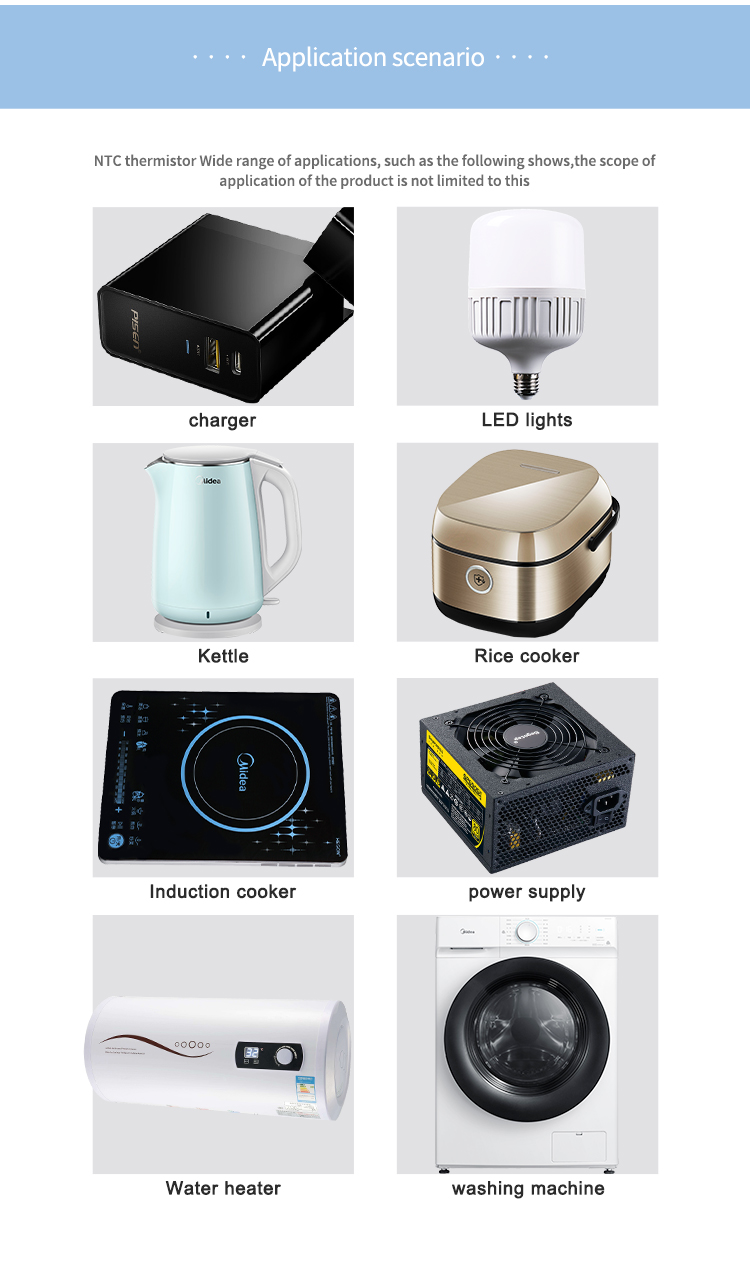

अर्ज

रूपांतरण वीज पुरवठा, स्विचिंग वीज पुरवठा, यूपीएस वीज पुरवठा

इलेक्ट्रॉनिक ऊर्जा-बचत दिवे, इलेक्ट्रॉनिक बॅलास्ट

इलेक्ट्रॉनिक सर्किट्स, पॉवर सर्किट्स इ.

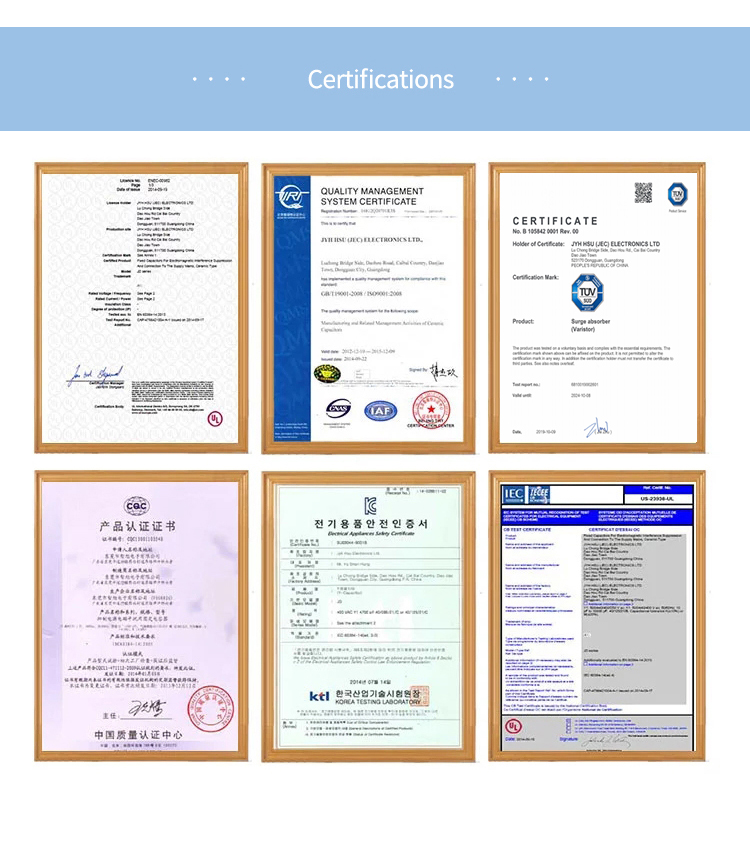

प्रमाणन

वारंवार विचारले जाणारे प्रश्न

प्रश्न: थर्मिस्टरचे बी मूल्य काय आहे?

A: B मूल्य हे एक भौतिक स्थिरांक आहे जे प्रतिरोध-तापमान संबंधांचे वर्णन करते, B चे मूल्य दोन विशिष्ट तापमानांमधील तापमान बदलांच्या प्रतिकाराची डिग्री प्रतिबिंबित करू शकते, जसे तापमान बदलते, त्याच परिस्थितीत मोठ्या B मूल्यासह उत्पादन , प्रतिकार मूल्य अधिक बदलते, म्हणजेच ते अधिक संवेदनशील असते.

प्रश्न: NTC किती प्रतिसाद देणारा आहे?

A: प्रतिसाद वेळ 62% किंवा नवीन तापमानापर्यंत पोहोचण्यासाठी लागणारा वेळ आणि वस्तुमानाचे कार्य म्हणून परिभाषित केले जाते.सेन्सर जितका लहान असेल तितका वेगवान प्रतिसाद.मेटल हाऊसिंगमध्ये कॅप्स्युलेट केल्यावर एक स्वतंत्र सेन्सर जलद प्रतिसाद देतो.मालिका NTC थर्मिस्टर सेन्सर्सचा ठराविक प्रतिसाद वेळ 15 सेकंदांपेक्षा कमी असतो.

प्रश्न: NTC चा आकार लहान आहे का?

A: इपॉक्सी कोटेड डिस्क्रिट सेन्सर्सचा कमाल बाह्य व्यास ०.९५" असतो आणि लघु काचेच्या सेन्सरचा कमाल बाह्य व्यास ०.१५" असतो.

प्रश्न: मी माझ्या अर्जासाठी रेझिस्टर मूल्य कसे निवडू?

उ: सर्वसाधारणपणे, कमी तापमानाच्या अनुप्रयोगांसाठी कमी प्रतिरोधक सेन्सर आणि उच्च तापमान अनुप्रयोगांसाठी उच्च प्रतिरोधक सेन्सर वापरा.आपल्याला आवश्यक असलेल्या तापमान श्रेणीमध्ये ऑपरेटिंग प्रतिरोध मूल्य असणे हे ध्येय आहे.